K5L4-5L 4 Cavity Blow Moulding Machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

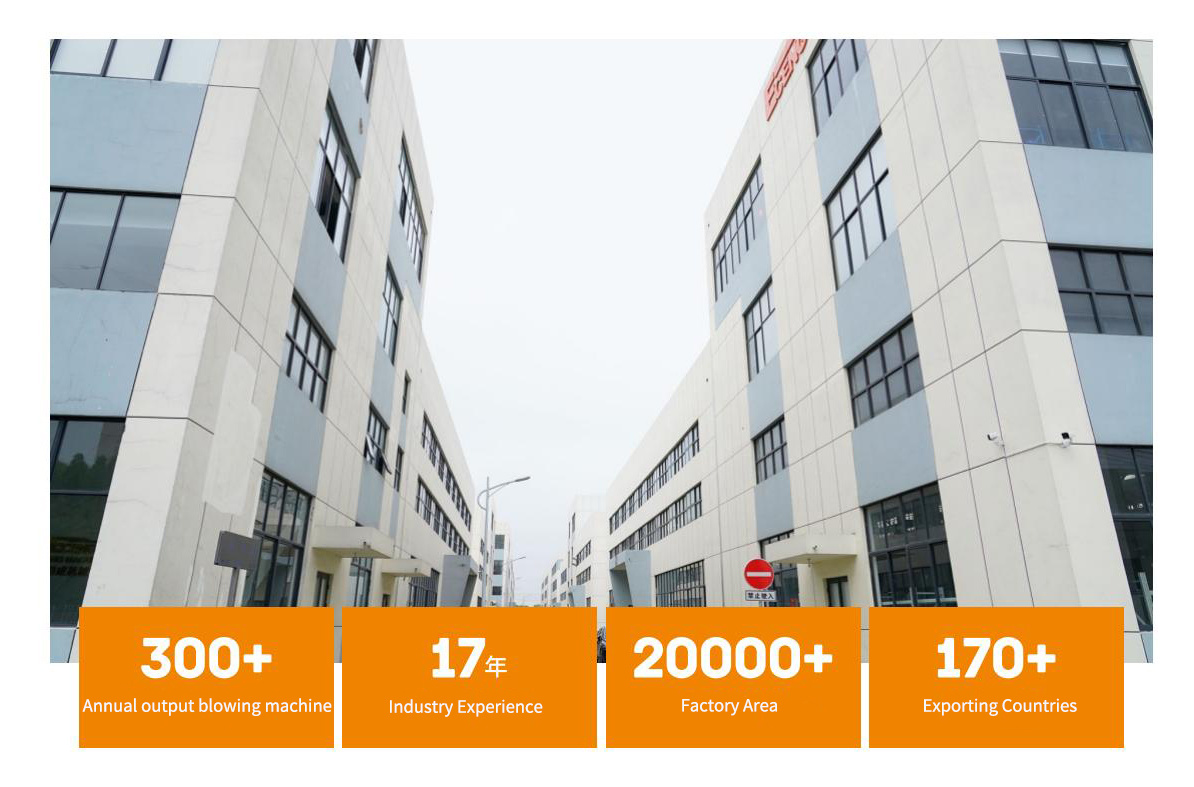

5L oil barrel blowing machine is widely used in 3L to 5.5L edible oil bottles, water bottles and other PET bottles. It is a linear blowing machine. Yucheng Machinery K series blowing equipment is faster and has lower energy consumption. The series of linear blowing machines can also be used for hot filling bottles and carbonated beverage bottles. The stretching rod is controlled by a servo motor to stretch the preform. The advantage is that it can be stretched in sections. The preform is positioned first to ensure the verticality of the preform during stretching, and then the secondary stretching is performed. Ensure the uniformity and consistency of the stretching of each preform.

1. This series of bottle blowing machines operates at high speed and stability, with accurate positioning. It adopts advanced microcomputer PLC control system, which is more stable.

2. The production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. Servo transmission system, fast speed, stable and reliable.

4. Suitable for flexible production of small quantities and varieties, with a wide range of applications to meet customer needs.

5. Energy utilization efficiency is improved, more energy is saved, and production capacity per unit time is increased.

6. The oil barrel bottle blowing machine has two operating modes: manual and fully automatic, with human-machine interface control and simple operation.

7. Each mechanical action has a safety self-locking device. When a process fails, the program will automatically switch to a safe state.

8. Compared with the Q series, the heat generation and noise of the K series bottle blowing equipment are significantly reduced.

9. The bottle scrap rate is less than 0.2%.

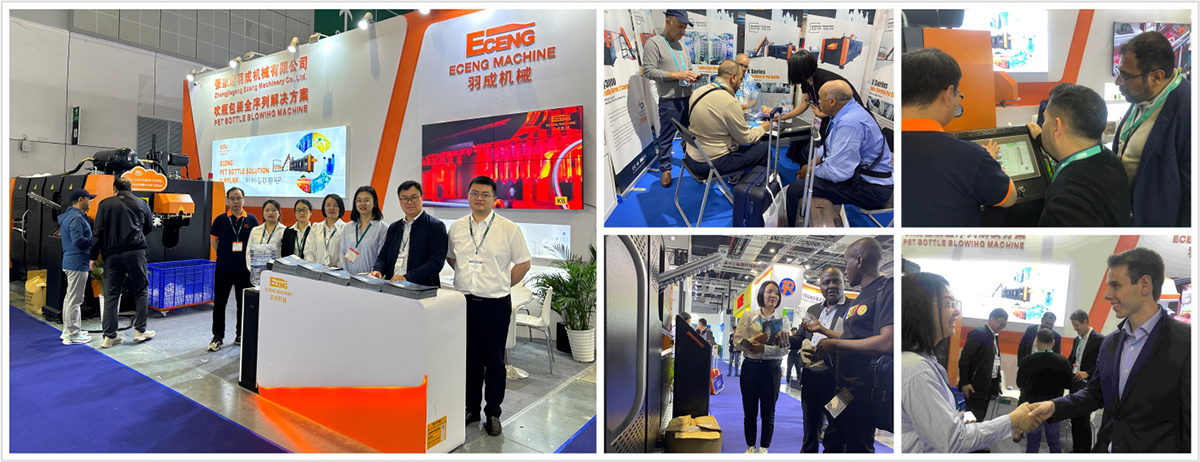

Delivery Display

Product Series

More products

Contact us to learn more about our business solutions