K10 10 Cavity Bottle Blowing Machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

K10 ten-cavity high-end bottle blowing machine is fully electric, energy-saving and environmentally friendly, with precise positioning, efficient energy utilization, and high hygiene standards. It is more suitable for the production of food, medicine, beverages and other products with extremely strict hygiene requirements. The bottle blowing equipment control system adopts the internationally advanced integrated computer intelligent control system, which has the advantages of high control accuracy, fault self-diagnosis, intelligent monitoring, data management, and graphical fault display.

1. The bottle blowing machine has two operating modes: manual and fully automatic, with human-machine interface control and simple operation.

2. Suitable for flexible production of small quantities and varieties, with a wide range of applications to meet customer needs.

3. Servo transmission system, high positioning accuracy, fast speed, stable and good reliability.

4. Each mechanical action has a safety self-locking device. When a process fails, the program will automatically switch to a safe state.

5. High-speed and stable operation, precise positioning, and the use of advanced microcomputer PLC control system can be more stable.

6. Energy utilization efficiency is improved, more energy is saved, and production capacity per unit time is increased.

7. The production process is fully automated, with the advantages of low investment, high efficiency, convenient operation, simple maintenance and safety.

8. Compared with the Q series, the heat generation and noise are significantly reduced.

9. The bottle scrapping rate of K series linear blow molding machines is less than 0.2%.

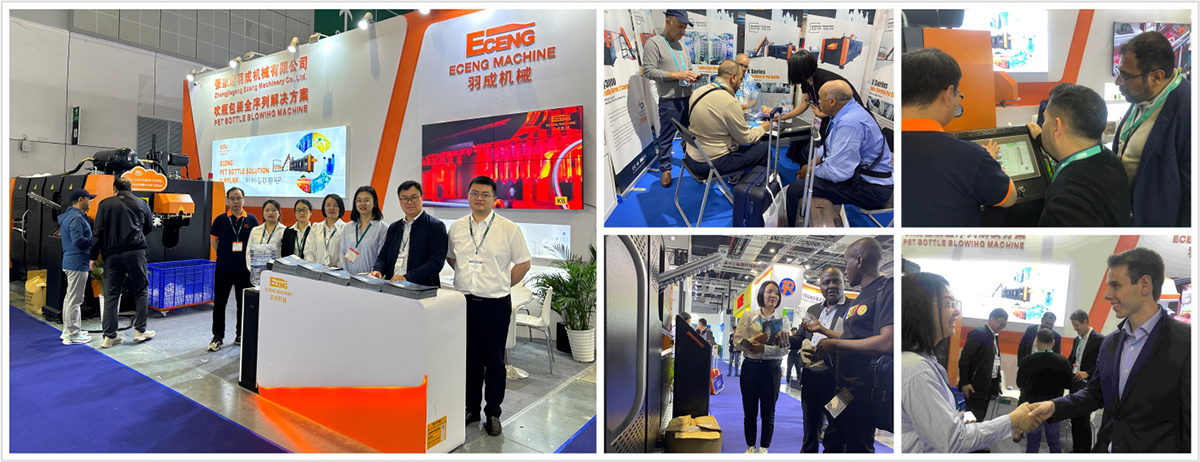

Delivery Display

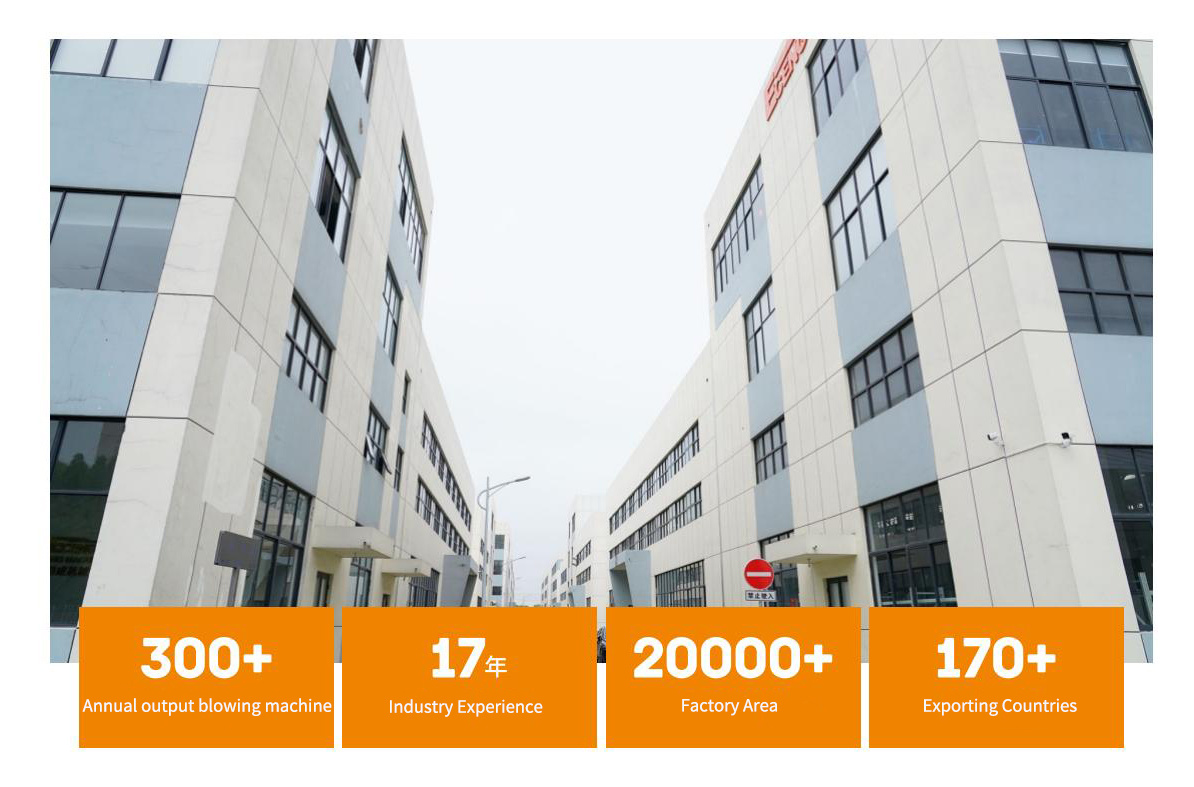

Product Series

More products

Contact us to learn more about our business solutions