YCQ-5L-2 2 Cavity Blow Moulding Machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

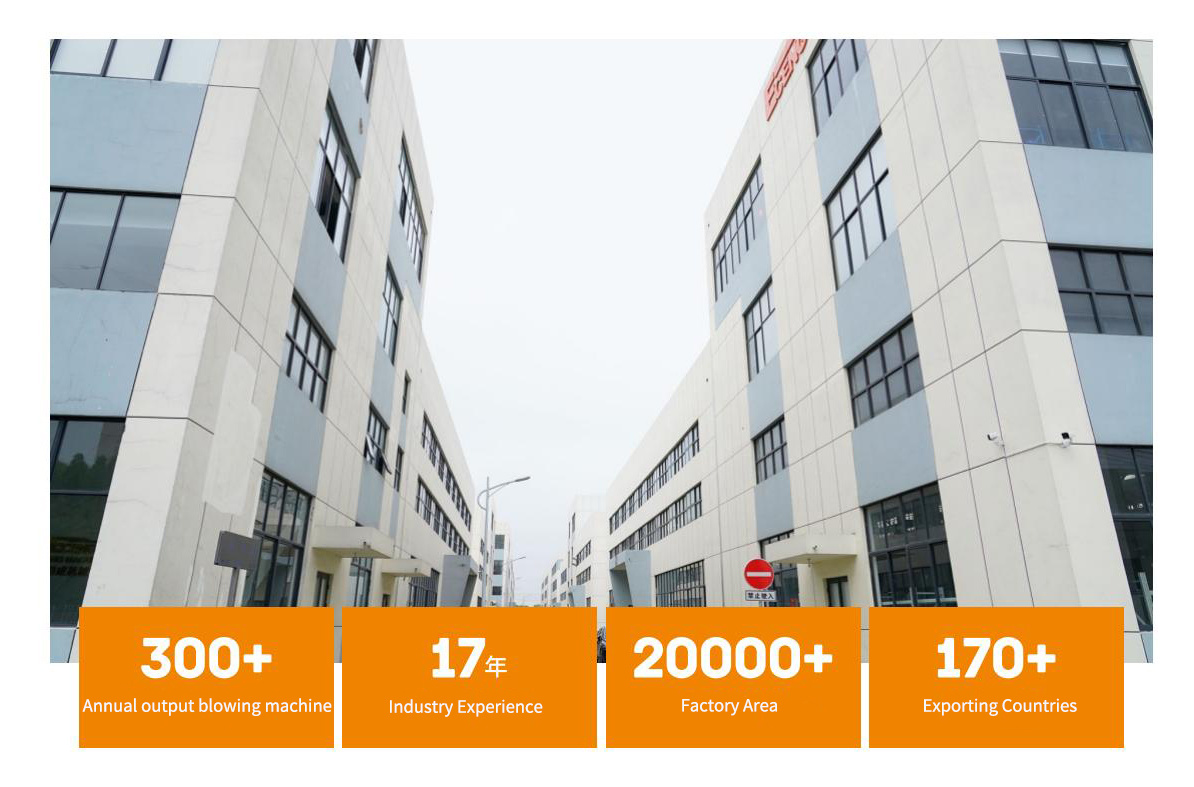

Yucheng Machinery's YCQ-5L-2 linear plastic bottle blowing machine uses a human-machine interface, is easy to operate, runs smoothly, has few faults, has a fast bottle blowing speed, is stable in bottle blowing, and consumes less energy. It is especially suitable for small and medium-sized oil factories and bottled water factories. This series of bottle blowing machines is suitable for the production of 5L large bottles, such as edible oil barrels, disposable water barrels, etc.

1. All parts are made of reasonable materials, precision processed and finely surface treated.

2. The rotary continuous preform loading mechanism is adopted, which has great compatibility with bottle preforms, stable and continuous preform loading, fast speed and high efficiency, overcoming the shortcomings of intermittent preform loading of traditional manipulators.

3. The servo motor is used to stretch the preform, with fast stretching speed, accurate stretching stroke, and the stretching stroke can be set arbitrarily.

4. This series of linear bottle blowing machines can directly deliver bottles to the filling line. The conveying mechanism is novel in design and the conveying is stable and reliable.

5. The spacing mechanism is reasonably designed, and the spacing is accurate and reliable.

6. There are mutual contraction programs between each operating mechanism to protect the machine.

7. During the blowing process, the bottle body is free of pollution.

8. This series of PET bottle blowing machines is highly energy-efficient.

9. Easy maintenance, safe operation, and very low noise from bottle blowing equipment.

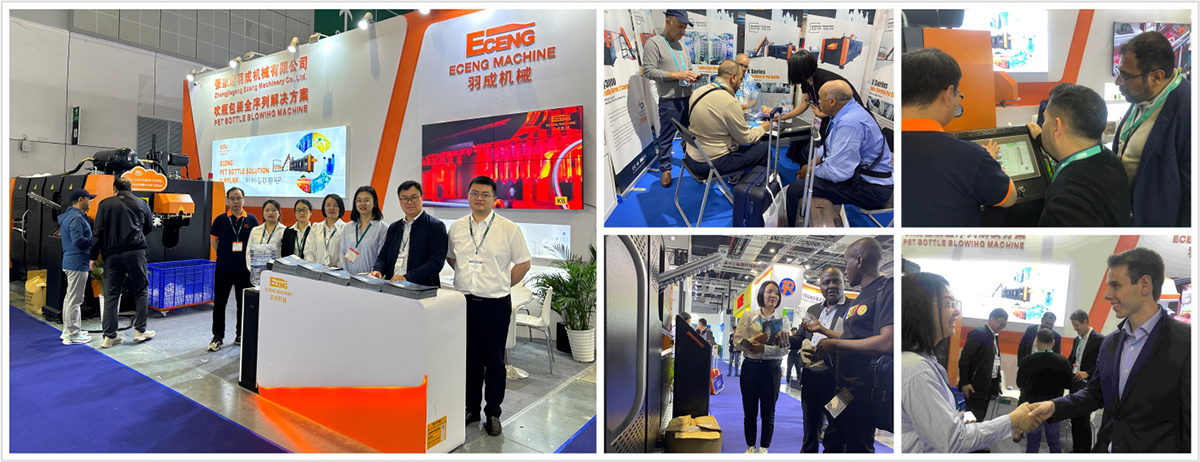

Delivery Display

Product Series

More products

Contact us to learn more about our business solutions