YC-2L-2 Semi Auto PET Blow Molding Machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

YC-2L-2 Semi-automatic Blow Molding Machine Introduction:

YC-2L-2 semi-automatic bottle blowing machine adopts double-axis crank arm clamping, which has stable clamping and fast operation speed. It also adopts far-infrared rotary oven for uniform heating.

The air circuit system is divided into two parts: action and blowing, to meet the needs of action and blowing without air pressure, and can provide stable high pressure to blow large-volume bottles of different shapes. Small size, low investment, one-person operation.

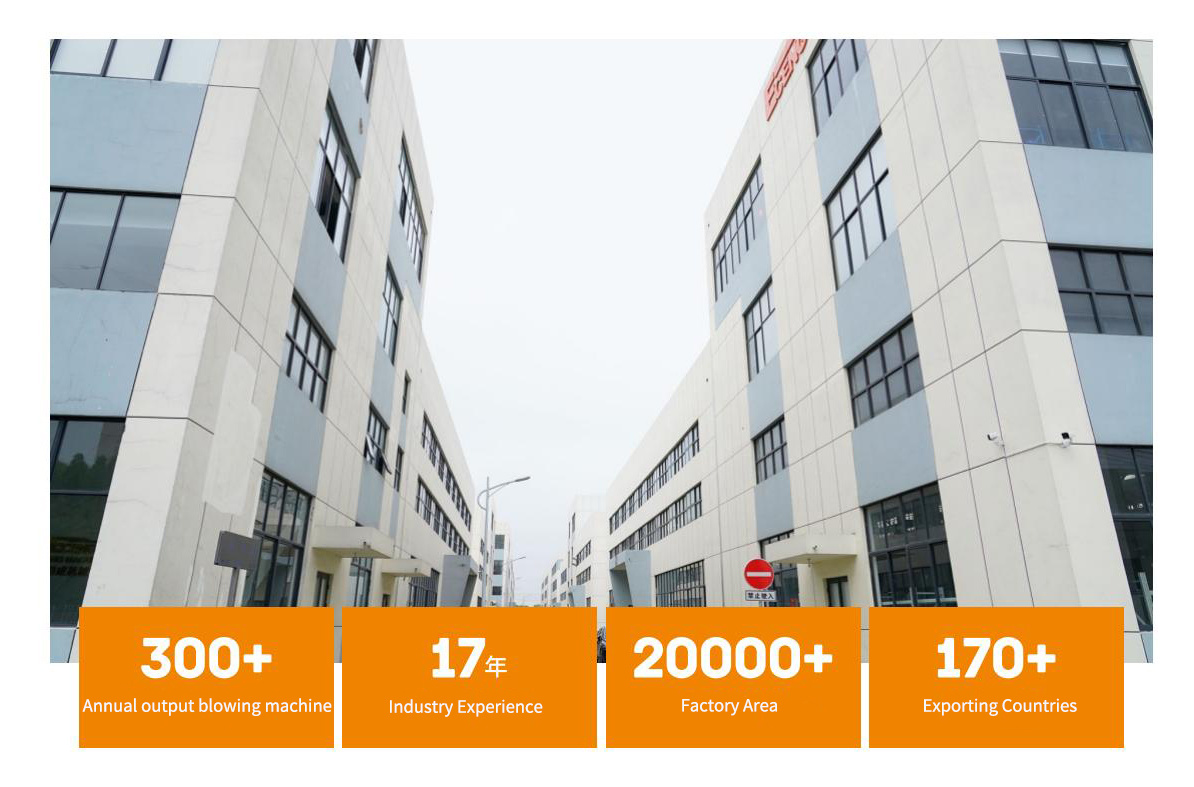

Yucheng Machinery's semi-automatic bottle blowing machine is well-equipped, with stable product quality and a wide range of applications. Bottle blowing machinery and equipment have the advantages of low investment, low cost, low power consumption, quick investment returns, easy operation, etc., and are available at a favorable price. It is an ideal packaging bottle blowing machinery and equipment widely used in mineral water, beverage, pesticide, chemical reagent, medicine, oil and other production plants.

YC-2L-2 semi-automatic bottle blowing machine features:

1. All machines are of improved design and meet IS9001 quality system and CE standards.

2. Controlled by a microcomputer, the technical parameters involved can be controlled more accurately.

3. The operation is simple and safe, only one person is needed and no special training is required.

4. Semi-automatic bottle blowing machine can blow PET carbonated beverage bottles, mineral water bottles, cosmetic bottles, hot filling bottles, pesticide bottles, oil bottles, etc.

5. The series of products blown by the bottle blowing machine have high transparency, high temperature up to about 120 degrees, and can withstand secondary high temperature sterilization. They are alternative products to glass bottles.

6. The semi-automatic bottle blowing equipment has low power consumption and high production capacity, which greatly reduces the customer's operating costs and improves the customer's production efficiency.

YC-2L-2 semi-automatic bottle blowing machine technical parameters:

Delivery Display

Product Series

More products

Contact us to learn more about our business solutions