YC-20L-1 Semi Auto Plastic Blowing Machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

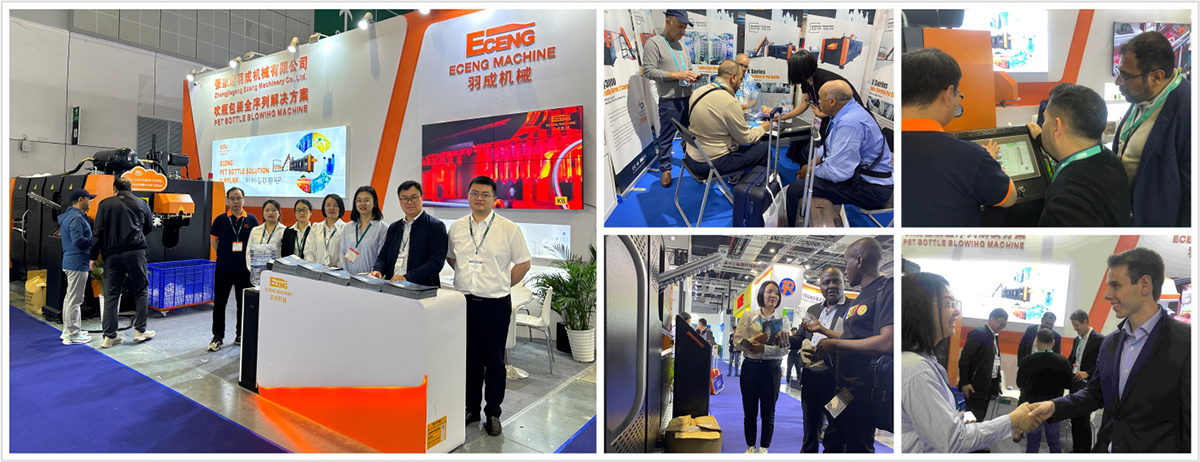

Delivery Display

Product Series

More products

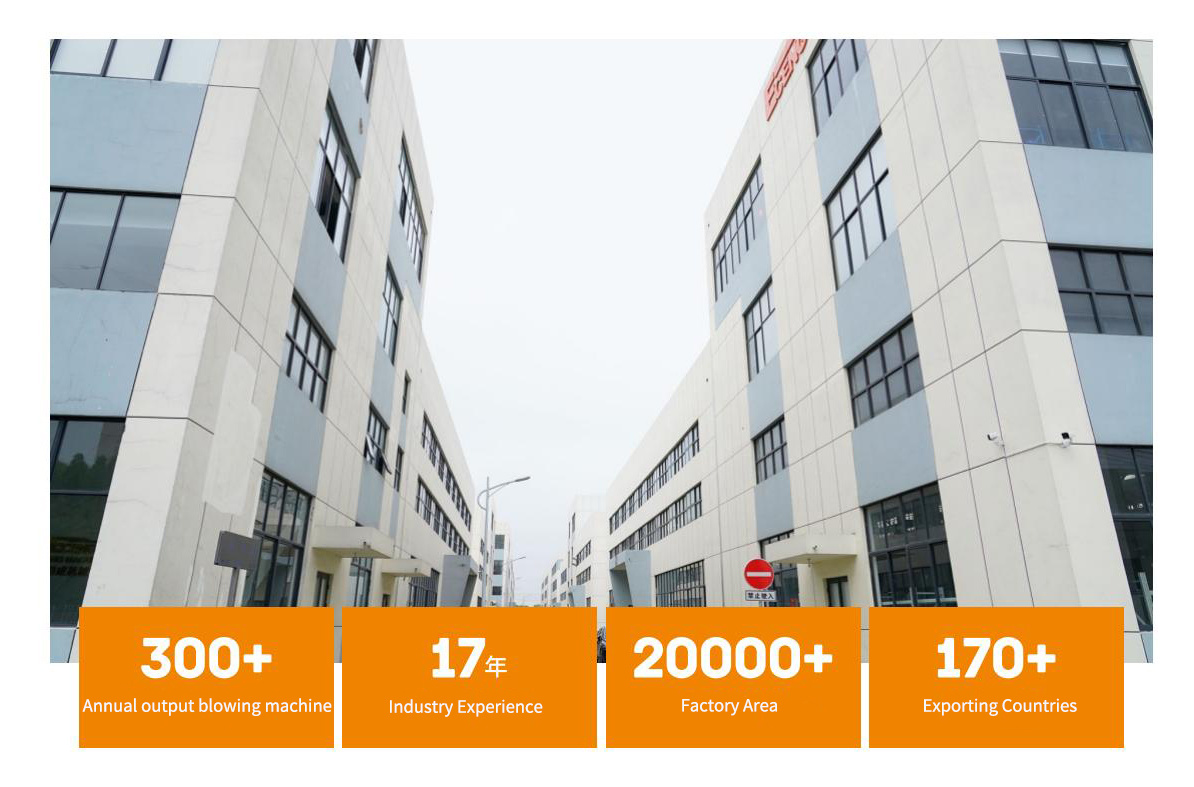

Contact us to learn more about our business solutions

Fill out the form below to receive news and industry insights about products delivered directly to your inbox