24 Cavity capping machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

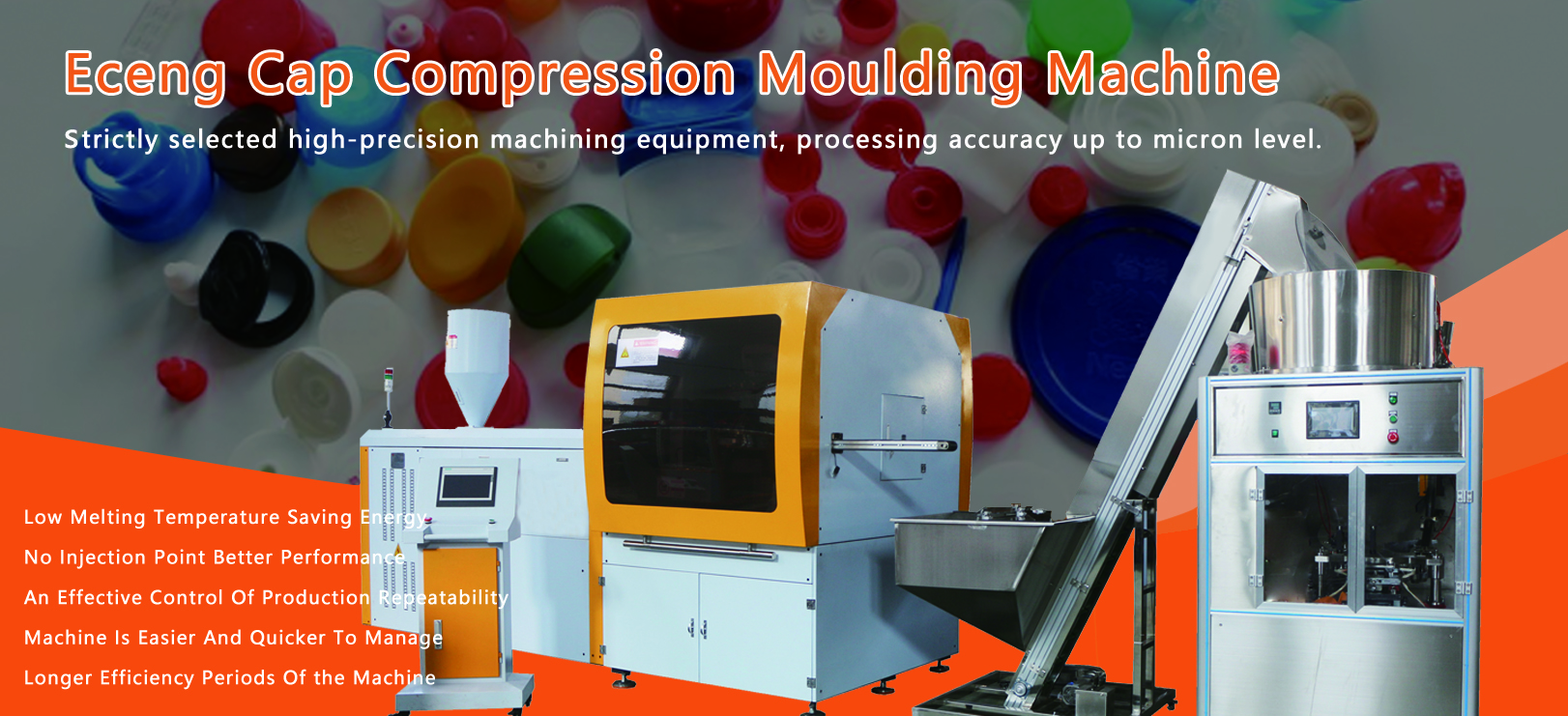

Eceng cap compression moulding machine

Eceng full automatic high speed cap compression moulding machine adopts hydraulic clamping principle, technic of rapid prototyping and mould release of low pressure, etc.to manufacture with continuous totation, widely used in the manufacture of bottle caps of carbonated beverage, mineral spring water, cosmetic products.

|

Model 1 |

24T |

|

Output Capacity |

20,000 - 28,000 |

|

Cap Diameter |

20-60mm |

|

Cap Height |

10-30mm |

|

Extrusion Heating Power |

12KW |

|

Extruder Motor Power |

11KW |

|

Cap Material |

PE/PP |

|

Cavity No. |

24 |

|

Mold Compression Motor |

3.5KW |

|

Hydraulic System Power |

17.5KW |

|

Power Supply |

380V/50HZ |

|

Air Consumption |

0.4m³/hr,0.8Mpa |

|

Machine Dimension |

4.2*1.8*2.2m |

|

Machine Weight |

5000KG |

1, The machine bottle production process without the injection point, good bottle products, beautiful appearance.

2, The machine adopts multi-speed rotating grinding repression approach to production, to ensure high productivity.

3, The machine rotary manner aeroassisted quit threaded mode, to avoid stripping the thread damage caused strong.

4, The machine is compact, fully automated operation.

5, The machine replacement material molds convenient and easier maintenance festival time.

Whether it’s mineral water bottle caps, beverage caps, or liquor inner seals, choose Eceng’s Cap Compression Molding Machines—power your production line with efficiency and reliability!

|

|

|

|

|

|

We Have The Right Products to Fit Your Needs Purchase

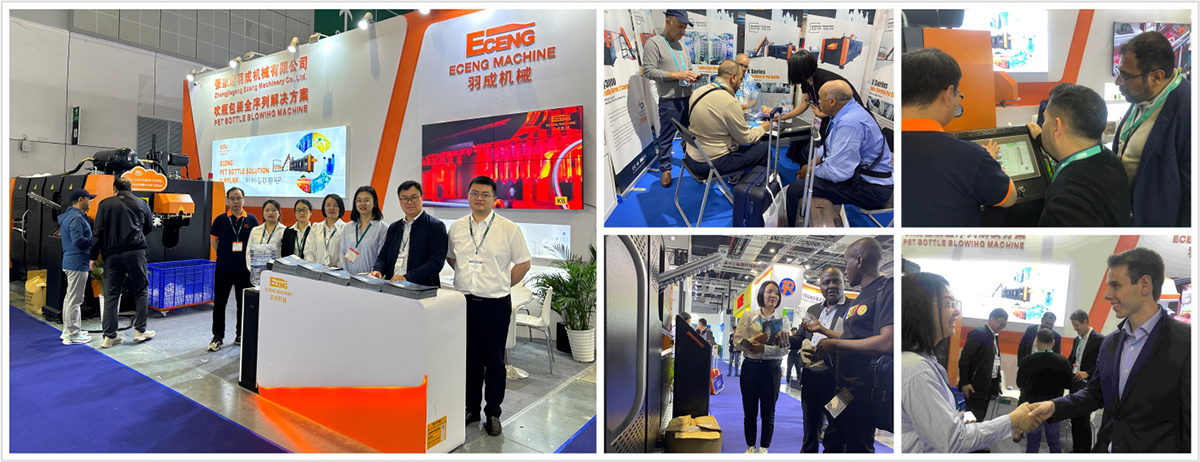

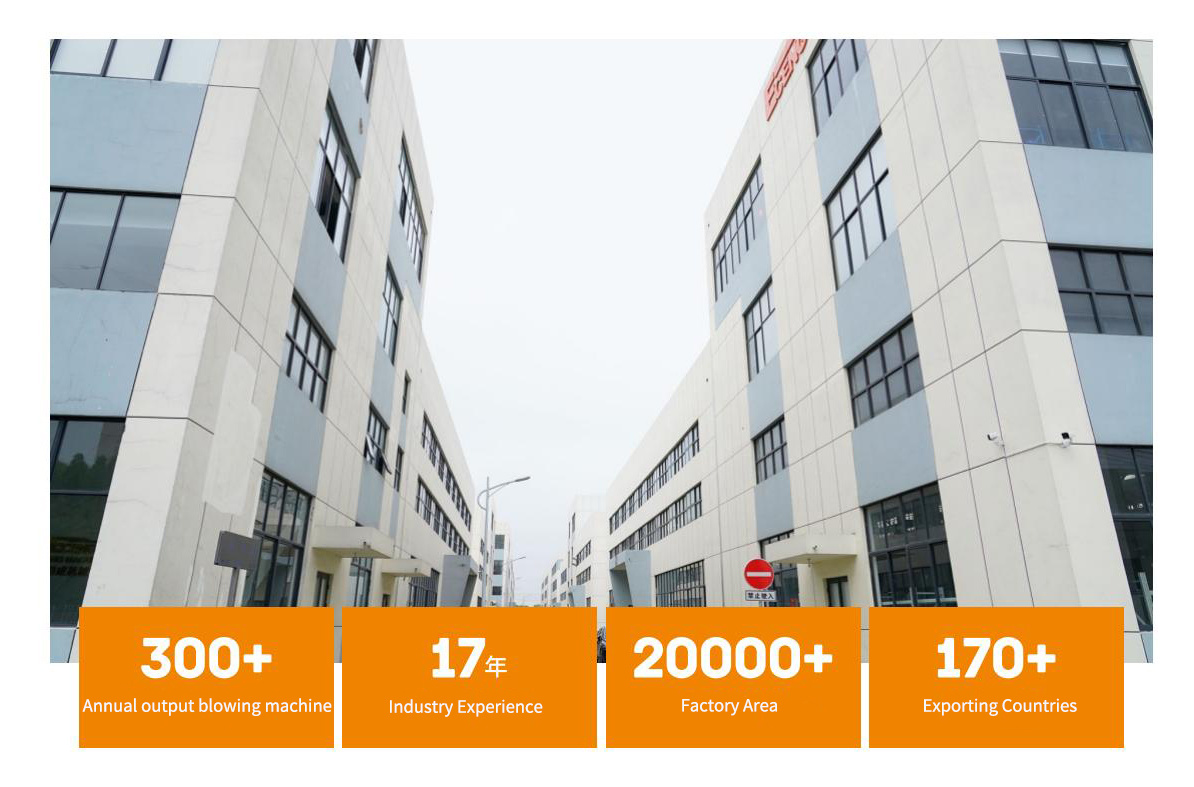

Zhangjiagang Eceng Machinery Co., Ltd., established in 2007,Our factory spans over 10,000 square meters, and we hold independent research and development patents. We offer a comprehensive production system for PET liquid packaging. Our main products include fully automatic and semi auto bottle blowing machines, self-adhesive labeling machines, OPP labeling machines, sleeve labeling machines,baler,Film shrink wrapping machine, carton packing machines,palletizing machines, blow moulds, injection pet preform mold, bottle cap molds, Bottle cap compression molding machines, air compressors, cold dryer, and chiller. As a leading one-stop service provider in PET liquid packaging, we supply factory direct products to over 170 countries and look forward to building long-term partnerships worldwide!

Delivery Display

Product Series

More products

Contact us to learn more about our business solutions