J4 4 Cavity PET Jar Manufacturing Machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

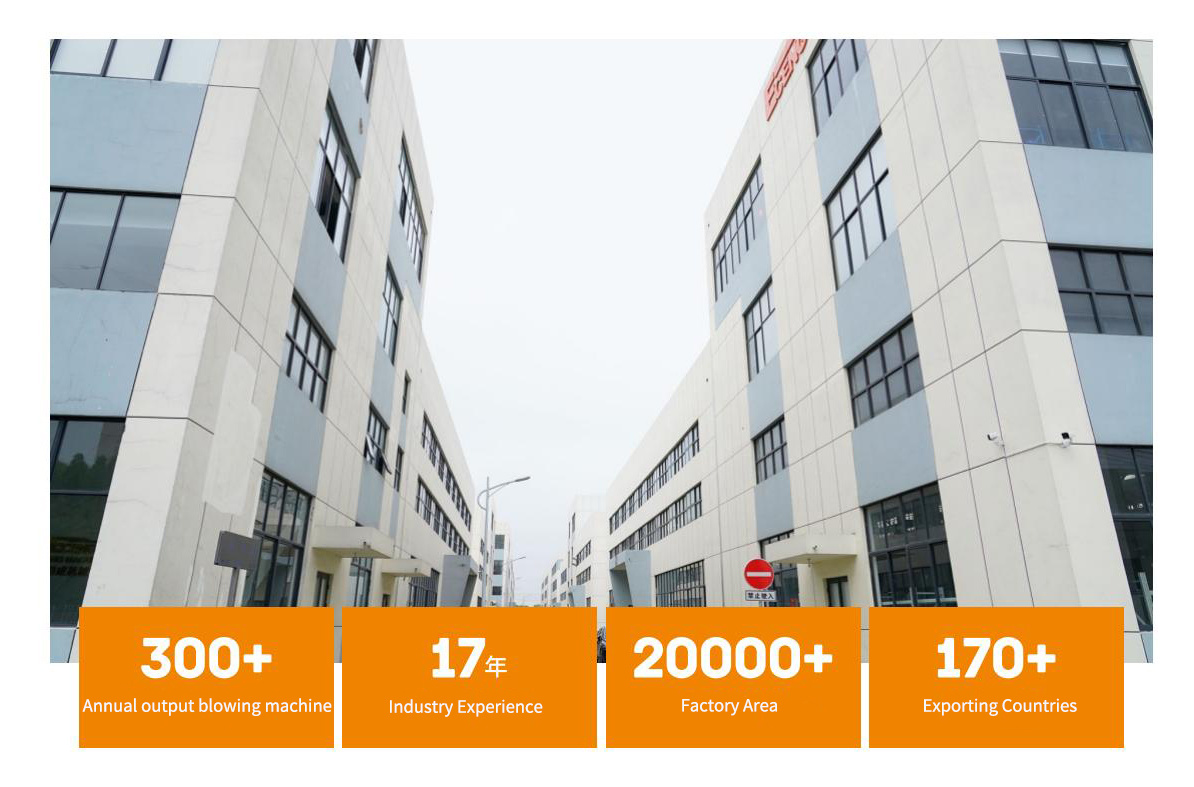

J4 plastic wide-mouth bottle blowing machine is a specialized equipment designed for large-diameter PET bottles. Yucheng Machinery's bottle blowing equipment has the characteristics of high degree of automation, wide versatility, and simple operation. The J series wide-mouth bottle blowing machine is particularly suitable for the production and processing of large-diameter bottles with a diameter of 50-180. The bottle blowing machine has precise positioning and adopts an advanced microcomputer PLC control system, which can be more stable.

1. The series of bottle blowing equipment is highly versatile, suitable for 50-180 diameters, with a high degree of automation, suitable for preform loading and automatic bottle unloading of wide-mouth bottles;

2. One person can control two to three devices, and the high output can be equipped with all-electric stretching and clamping;

3. The heat has strong penetration and the preform rotates itself, so that the preform receives uniform heat during the preheating process;

4. Safe, reliable and unique valve position design makes the bottle blowing process easier to control;

5. There is a safety locking device in each mechanical action process to protect the operator's safety;

6. J series bottle blowing machine has low cost, high efficiency, easy operation, easy maintenance, etc., and advanced automatic process flow;

7. It has two operation modes: automatic and manual;

8. Use different air pressures for bottle blowing and machine operation, which is energy-saving and environmentally friendly;

9. Easy to install and start, with low scrap rate.

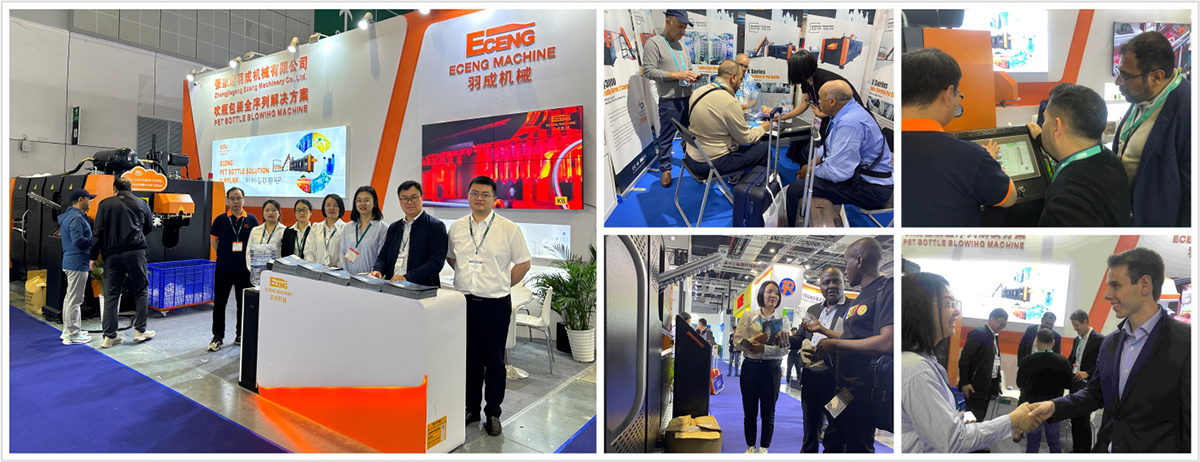

Delivery Display

Product Series

More products

Contact us to learn more about our business solutions