H3 Hand Feeding Blow Molding Machine

In the process, the stretching rod is controlled by the servo motor to stretch the bottle embryo.

Key words: bottle blowing machine

Classification:

Yucheng H3 beverage bottle manual blow molding machine is a professional blow molding equipment designed for cosmetic bottles, daily bottles, special-shaped bottles, and small-volume conventional bottles (water bottles, beverage bottles, oil bottles, etc.). This blow molding machine is easy to operate and has a wide range of applications. It is suitable for PET bottles of various calibers and uses. The H series does not carry automatic feeding equipment, which is replaced by manual feeding. It is a low-cost, stable, reliable, safe and practical alternative to traditional semi-automatic equipment.

1. Wide versatility, suitable for various calibers and shapes, especially for daily chemical products;

2. It is not equipped with an automatic feeding system, so it is easier and quicker to update and change models;

3. High safety, no contact with mold clamping and high-pressure blowing unit, away from dangerous areas;

4. Low labor intensity;

5. Equipped with advanced PLC control system, it has stable and excellent performance;

6. The heat has strong penetrability and the preform rotates itself, so that the preform receives uniform heat during the preheating process;

7. There is a safety locking device in each mechanical action process to protect the operator's safety;

8. Use different air pressures for bottle blowing and machine operation, which is energy-saving and environmentally friendly;

9. Use air cylinders instead of hydraulic cylinders, which has less pollution and lower noise;

10. This series of bottle blowing machines are low-cost, high-efficiency, easy to operate, easy to maintain, and have advanced automatic process flow;

11. It has two operation modes: automatic and manual;

12. Avoid contamination of the bottle and easy to install and start.

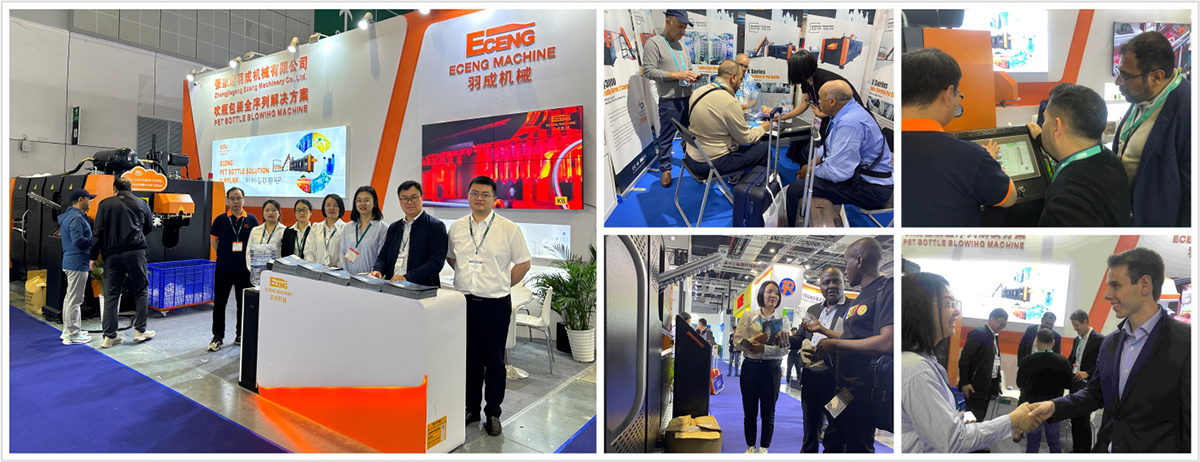

Delivery Display

Product Series

More products

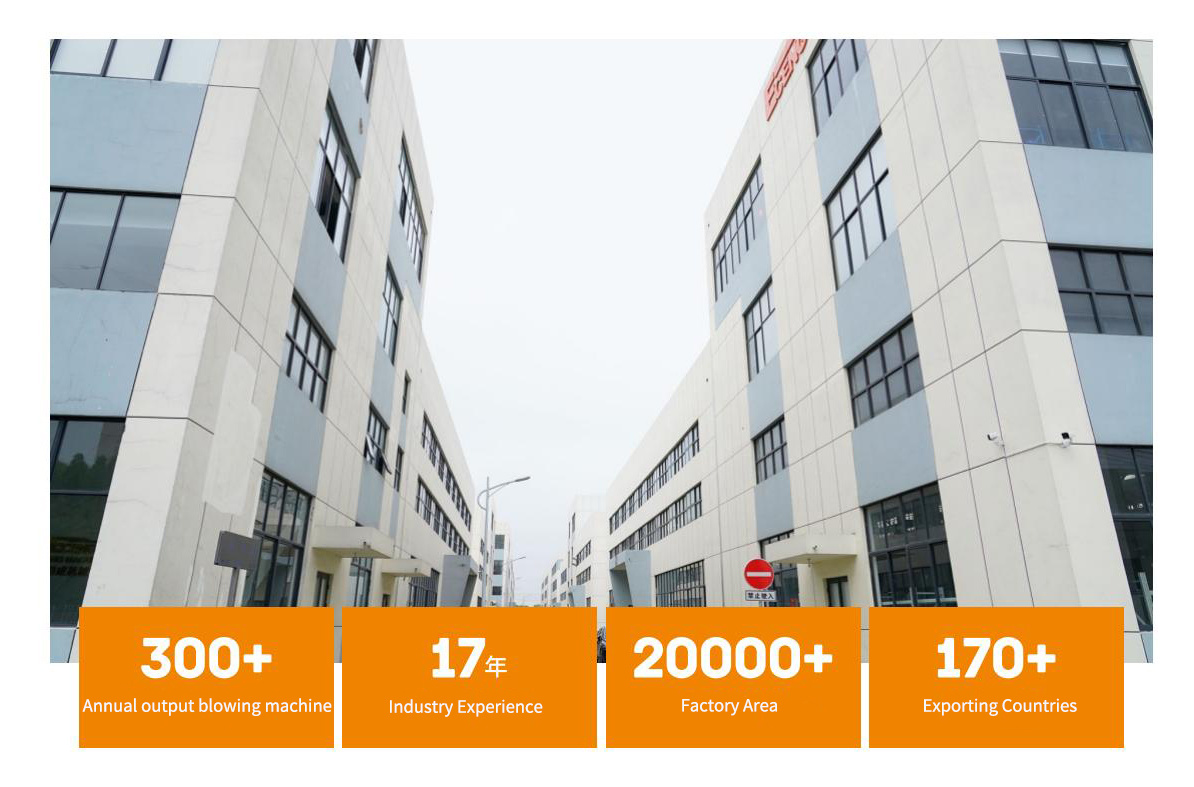

Contact us to learn more about our business solutions